Unlocking Efficiency: The Future of CNC Auto Parts Manufacturing

Time:

09 Sep,2025

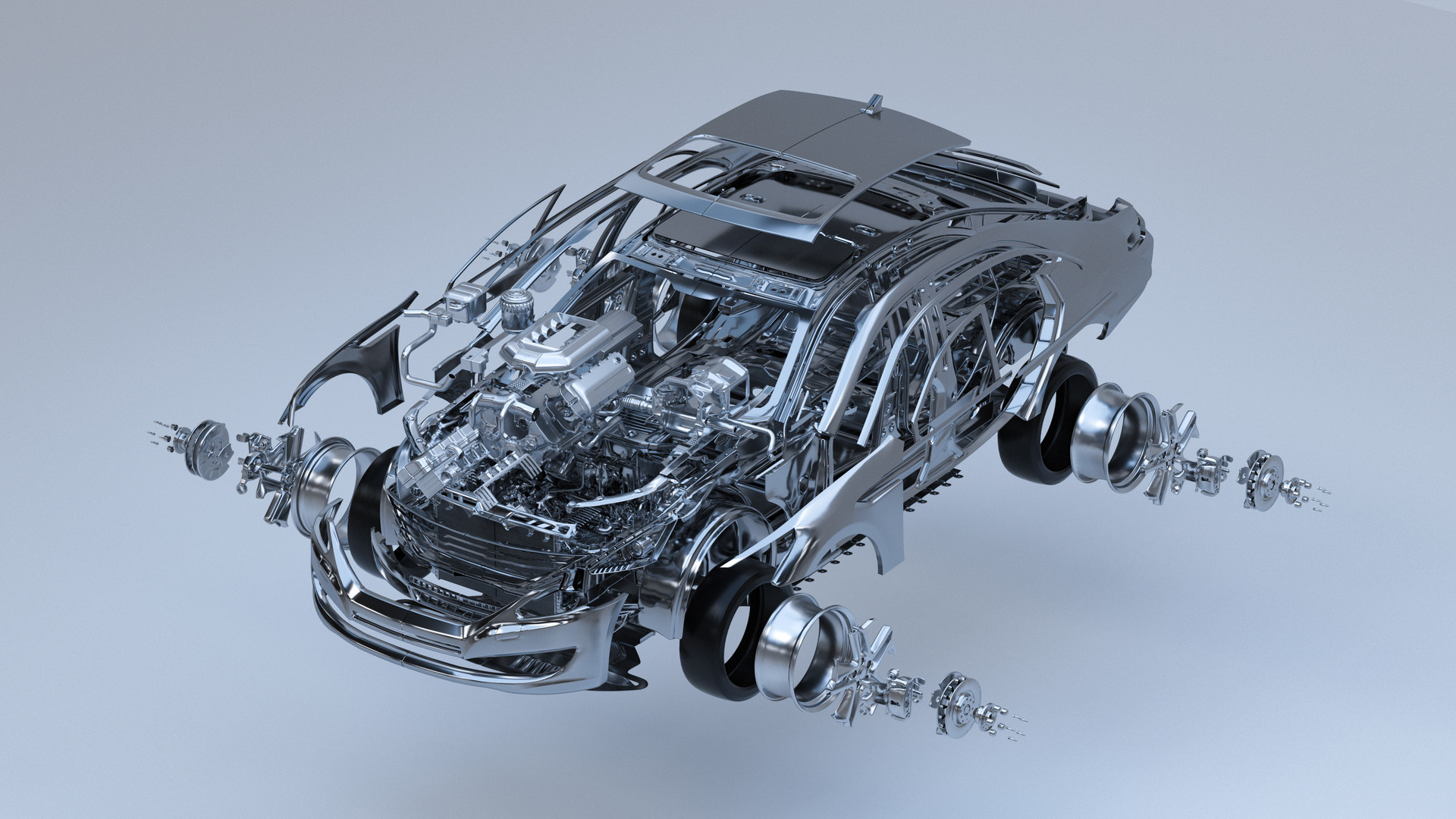

The Revolution of CNC Auto Parts

Hey there, gearheads and industry innovators! Have you ever wondered how modern vehicles are assembled with such precision? Well, pull up a chair and let's dive into the world of CNC auto parts, where technology meets creativity in manufacturing.

What is CNC?

CNC stands for Computer Numerical Control, and it's a game-changer in the manufacturing sector. Imagine a robot that can cut, mill, and shape materials with pixel-perfect accuracy. That's CNC for you! This tech takes the guesswork out of creating parts, ensuring consistency and high quality every time.

Why CNC Auto Parts?

So, why should you care about CNC auto parts? Well, let's break it down:

- Precision: CNC machines operate with incredible accuracy, producing parts that fit together flawlessly.

- Efficiency: With automated processes, production times are reduced significantly, allowing manufacturers to crank out more parts in less time.

- Flexibility: Need a custom part? No problem! CNC machines can be reprogrammed to create a variety of components without the need for extensive retooling.

Industry Applications

From automotive to aerospace, CNC auto parts are everywhere! Here are just a few industries reaping the benefits:

- Automotive: Think engines, brackets, and everything in between. CNC parts ensure vehicles are not just functional but also safe.

- Aerospace: With the need for lightweight and durable materials, CNC machining is pivotal in crafting components that can withstand extreme conditions.

- Medical: From surgical instruments to orthopedic implants, precision is crucial, and CNC delivers!

Challenges in the CNC World

Now, don't get too starry-eyed just yet! The world of CNC auto parts isn't all sunshine and rainbows. There are challenges, too:

- Cost: High-quality CNC machines can be a hefty investment.

- Skill Gap: Operating these machines requires specialized training that isn't always readily available.

- Maintenance: Regular upkeep is essential to ensure machines remain in top shape.

The Future is Bright!

Despite the challenges, the future of CNC auto parts manufacturing looks brighter than ever. With advancements in technology like AI and IoT, we're on the cusp of even more efficient processes. Imagine CNC machines that can predict maintenance needs before they break down—now that's what I call smart manufacturing!

Get Involved!

Are you feeling inspired? Whether you're a budding engineer or a seasoned pro, there's a place for you in the CNC world. Start by learning the basics of CNC programming, or delve into CAD (Computer-Aided Design) software to get a feel for what goes into creating those precise designs.

Wrapping Up

In conclusion, CNC auto parts are not just a trend—they're the backbone of modern manufacturing. As we embrace these technologies, we're not just building parts; we're crafting the future. So, gear up and get ready to ride the wave of innovation!

Recommended