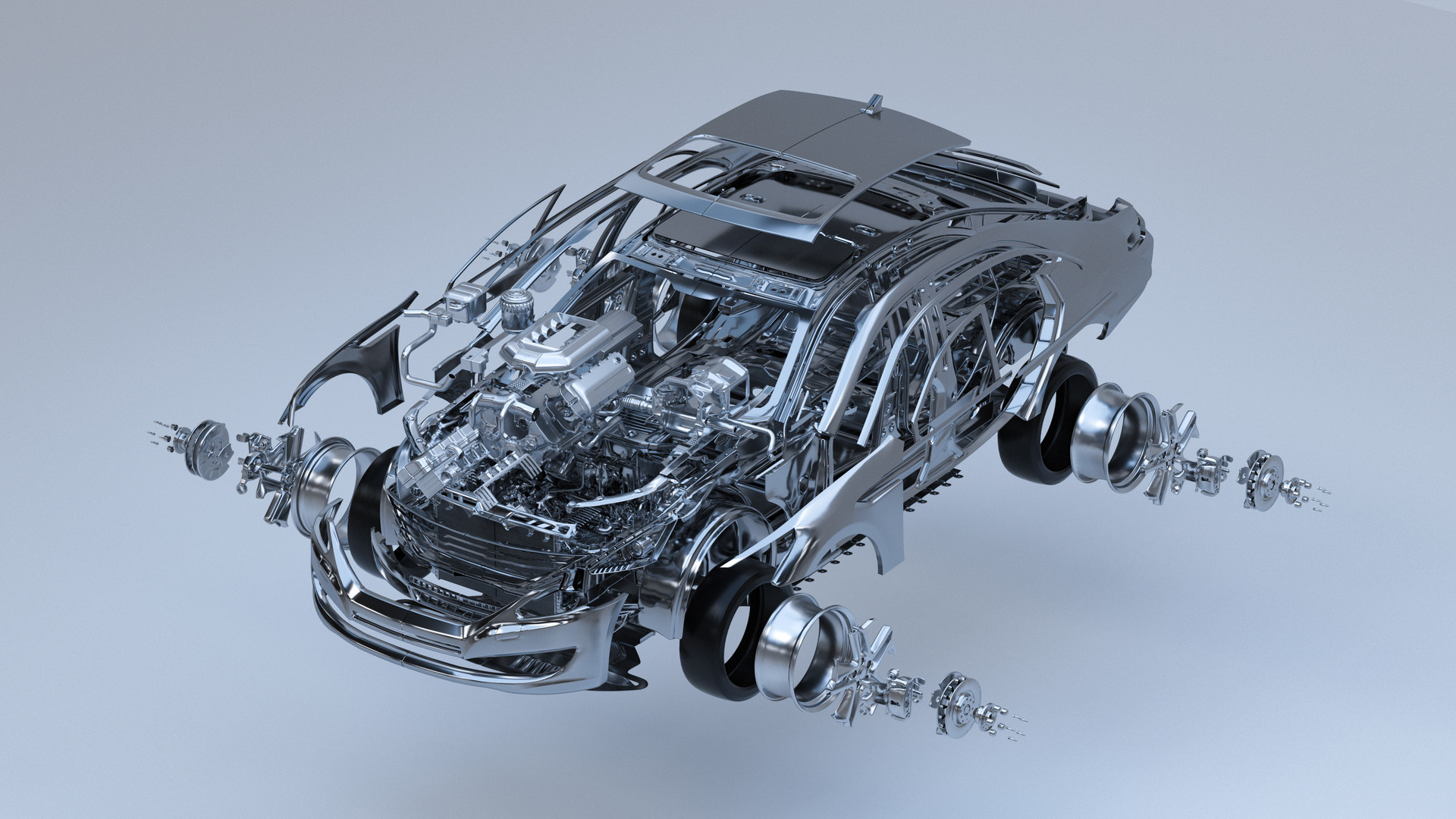

Revving Up: The Impact of CNC Auto Parts in the Automotive Industry

Time:

11 Sep,2025

The Rise of CNC Auto Parts

In today's fast-paced automotive industry, precision is not just a luxury; it's a necessity. Enter CNC auto parts—those meticulously crafted components that have become the backbone of modern vehicle manufacturing. But what does CNC stand for? Well, it's short for Computer Numerical Control, a process that's transforming how manufacturers approach production. Buckle up, as we dive into the world of CNC auto parts and their industry applications!

Why CNC Auto Parts Matter

CNC auto parts are the unsung heroes in the automotive realm. They bring a level of accuracy to manufacturing that's hard to beat. Think about it: a misaligned part can lead to costly repairs and safety hazards. With CNC technology, manufacturers can create parts that fit like a glove, reducing waste and enhancing overall efficiency. And let's face it, in an industry where margins are tighter than ever, every penny counts!

From Concept to Creation: A Case Study

Let's take a gander at a real-world example. Imagine a startup company, Speedy Motors, that sets its sights on producing high-performance racing cars. They soon realize that the key to their success lies in the precision of their CNC auto parts. By utilizing CNC machining, they can produce lightweight yet durable components that give their vehicles an edge on the track.

In just a few years, Speedy Motors becomes a household name in the racing community. Their secret? Investing in cutting-edge CNC technology that allows them to produce parts quickly and accurately. With their CNC auto parts, they can not only meet but exceed the demanding standards of professional racers. Talk about a game-changer!

The Benefits of CNC Auto Parts

So, what are the perks of using CNC auto parts in manufacturing? Here's a quick rundown:

- Precision: CNC machines can replicate parts to the exact specifications needed, ensuring uniformity across the board.

- Efficiency: Automated processes reduce production time, allowing manufacturers to churn out parts at an impressive rate.

- Flexibility: Need a custom part? CNC machining can handle small runs and prototypes with ease.

- Cost-Effective: Although the upfront investment can be hefty, the long-term savings on labor and material waste are significant.

Challenges in the CNC Auto Parts Sphere

Now, it's not all smooth sailing in the world of CNC auto parts. There are challenges that manufacturers face. For instance, initial costs can be a deterrent for smaller businesses. Additionally, keeping up with ever-evolving technology demands continuous learning and investment.

Moreover, skilled operators are a must! Without proper training, the potential of CNC machines can go untapped, leading to errors and inefficiencies. It's like having a fancy sports car but not knowing how to drive it properly!

Looking Ahead: The Future of CNC Auto Parts

The future of CNC auto parts looks bright and full of potential. As technology advances, we can expect even greater innovations in automation and robotics, which will further enhance the capabilities of CNC machining. Imagine parts being produced on-demand, reducing lead times to mere hours instead of weeks. Talk about efficiency!

Moreover, sustainability is becoming a hot topic. CNC technology can produce less waste and utilize eco-friendly materials, aligning with the automotive industry's push for greener solutions.

Final Thoughts

In a nutshell, CNC auto parts are the unsung champions of the automotive industry. They drive precision, efficiency, and innovation, all while helping manufacturers stay competitive. Whether you're a small startup or a major automotive player, investing in CNC technology can pave the way for success. So, if you haven't hopped on the CNC bandwagon yet, what are you waiting for? The road to success is paved with precision!

Recommended