The Unsung Heroes: Exploring Forged Automotive Parts

Time:

04 Sep,2025

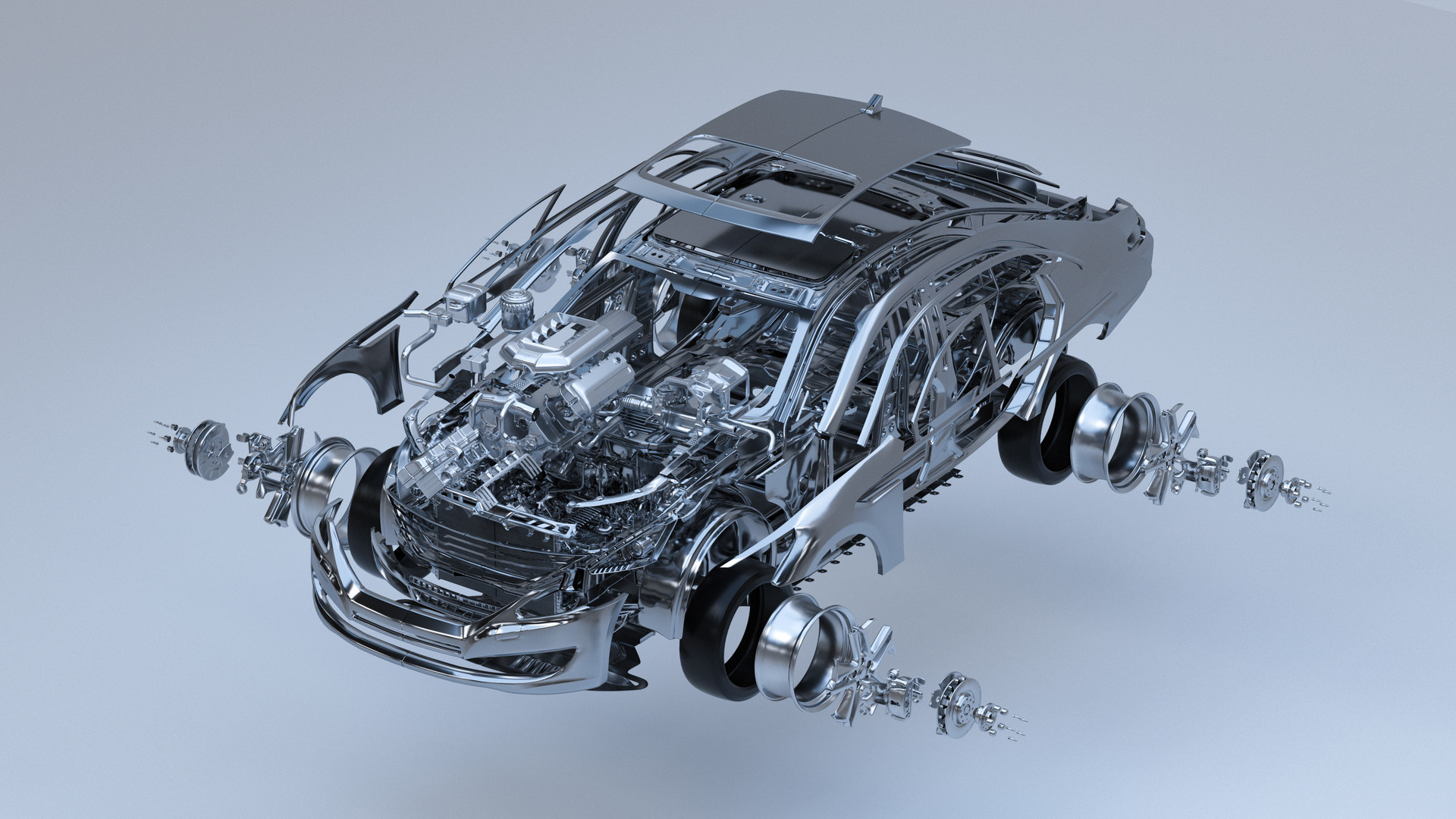

Understanding Forged Automotive Parts

When it comes to automotive manufacturing, the term forged automotive parts pops up often, but what does it really mean? Well, buckle up, because we're about to take a thrilling ride through the world of forging!

What Are Forged Automotive Parts?

In simple terms, forged automotive parts are components created through the process of forging, which involves shaping metal using compressive forces. Think of it as molding clay, but with a whole lot more muscle! The process enhances the strength and durability of the metal, making forged parts a go-to choice in the automotive industry.

Why Choose Forged Parts?

Now, you might be wondering, why should I care? Well, here's the scoop: forged automotive parts are known for their superior strength, reliability, and resistance to wear and tear. They can withstand the high-stress environments of a running engine, and let's be honest, nobody wants a car that breaks down unexpectedly, right?

The Forging Process: A Closer Look

So, how are these mighty parts made? The forging process typically involves heating the metal until it's malleable, then using a hammer or press to shape it. This is where the magic happens! The result? A part that's not only strong but also has a fine grain structure, ensuring it can handle the rigors of the road.

From Raw Material to Finished Product

Picture this: raw metal gets heated, hammered, and then cooled to perfection. This transformation is what sets forged parts apart from their cast counterparts. While casting can leave air pockets and imperfections, forging compacts the metal, leading to a uniform structure. That's why many high-performance vehicles use forged components—because when speed and safety are on the line, every little bit counts!

Common Applications of Forged Parts

Forged automotive parts can be found in numerous applications, from engine components to suspension systems. For instance, crankshafts, connecting rods, and gears are often forged to ensure they can withstand high levels of stress. It's like having a superhero in your car—strong, reliable, and always ready to save the day!

Benefits Beyond Strength

But wait, there's more! Forged parts aren't just about brute strength. They also offer excellent fatigue resistance, which means they can handle repeated stress without failing. Plus, they often have a better weight-to-strength ratio compared to other options. That's a win-win for performance enthusiasts looking to shave off extra pounds from their ride.

The Cost Factor

Now, let's talk turkey: the cost. It's true that forged automotive parts often come with a heftier price tag than their cast or machined counterparts. But hey, you get what you pay for! Investing in quality can save you a ton of cash in the long run by reducing maintenance and replacement costs.

Conclusion: A Smart Choice for Every Driver

In a nutshell, forged automotive parts are an excellent choice for anyone looking to enhance their vehicle's performance and longevity. Whether you're a weekend warrior on the racetrack or just someone who wants a reliable car for daily commutes, these parts are worth considering. So, next time you pop the hood, take a moment to appreciate the engineering marvels that are forged parts—they truly are the unsung heroes of the automotive world!

Recommended