The Rise of Forged Automotive Parts: Strength Meets Innovation

Time:

05 Sep,2025

The Rise of Forged Automotive Parts: Strength Meets Innovation

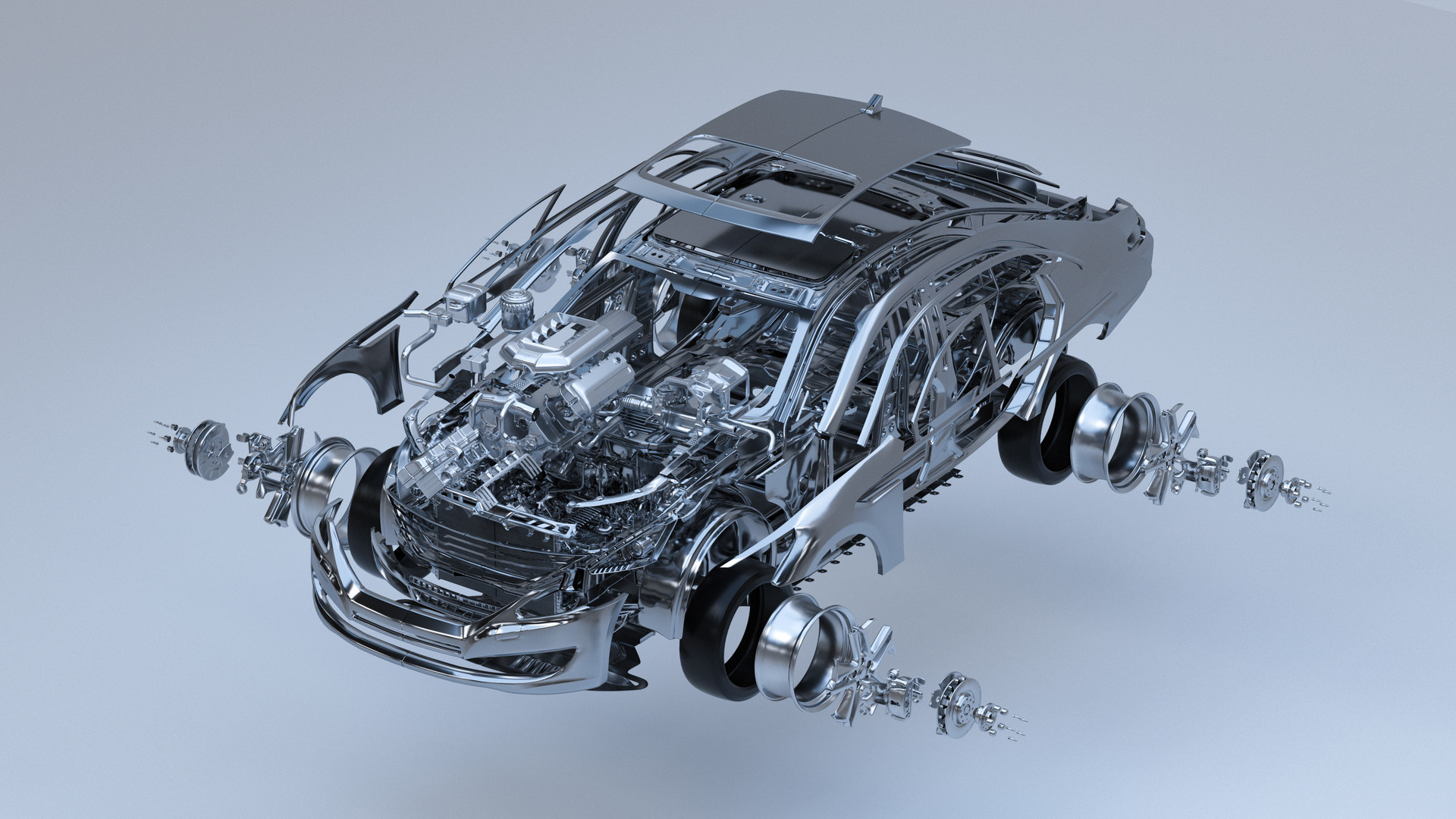

When it comes to the automotive industry, strength and reliability are top priorities. Enter forged automotive parts—the unsung heroes of the car manufacturing world! These bad boys are engineered to withstand the pressures of everyday driving, making them essential for performance vehicles and everyday rides alike.

What Are Forged Automotive Parts?

So, what exactly are these forged automotive parts? In a nutshell, they're components made from a solid piece of metal that's heated and shaped through hammering or pressing. This process creates a denser and more durable product than traditional casting methods. Think of it like turning a lump of dough into a perfectly shaped loaf of bread—only this loaf can handle the heat of the road!

Benefits Galore!

Now, you might be wondering, why all the fuss about forged parts? Well, let's break it down:

- Durability: Forged parts can take a beating. Their tight grain structure makes them tougher than cast alternatives.

- Weight Savings: Lighter parts mean better performance. Reducing weight without compromising strength is a win-win.

- Cost-Effectiveness: While the initial investment might be higher, the longevity of these parts can save manufacturers money in the long run.

Real-World Applications

Let's get down to brass tacks. Where are these forged automotive parts being used? Anywhere you look, they're making waves:

- High-Performance Cars: Sports car enthusiasts swear by forged pistons and connecting rods for that extra kick!

- Heavy-Duty Trucks: Forged components can handle the load, making them ideal for commercial vehicles.

- Motorcycles: Lightweight forged parts help bikers achieve superior speed and agility on the road.

The Manufacturing Process

Alright, hold onto your hats! The manufacturing of forged automotive parts is quite the spectacle:

First, raw materials are heated to a temperature where they become malleable. Then, they're shaped under high pressure, often using a hydraulic press, which transforms them into the desired geometry. Finally, they undergo heat treatment to enhance their mechanical properties. It's like watching a blacksmith at work—pure artistry!

Challenges and Solutions

No industry is without its hiccups. The forging process can be energy-intensive, and the cost of materials can fluctuate. However, advancements in technology are paving the way for more efficient manufacturing methods. Companies are investing in automation and innovative materials to keep up with demand.

The Future of Forged Parts

Looking ahead, the future of forged automotive parts seems bright! With the push for electric vehicles (EVs) and lighter materials, the demand for high-strength components is only going to grow. Manufacturers are already exploring how forged parts can be integrated into EV designs, ensuring they remain a cornerstone of modern automotive engineering.

Final Thoughts

So, to sum it all up, forged automotive parts are not just a trend; they're a necessity in today's fast-paced automotive landscape. Strength, durability, and innovation? Yes, please! Whether you're a gearhead or just someone who appreciates a good ride, it's clear that forged parts are here to stay. Next time you rev up your engine, just remember—there's a bit of forged magic under the hood!

Recommended