The Power of Forged Automotive Parts: Revolutionizing the Industry

Time:

07 Sep,2025

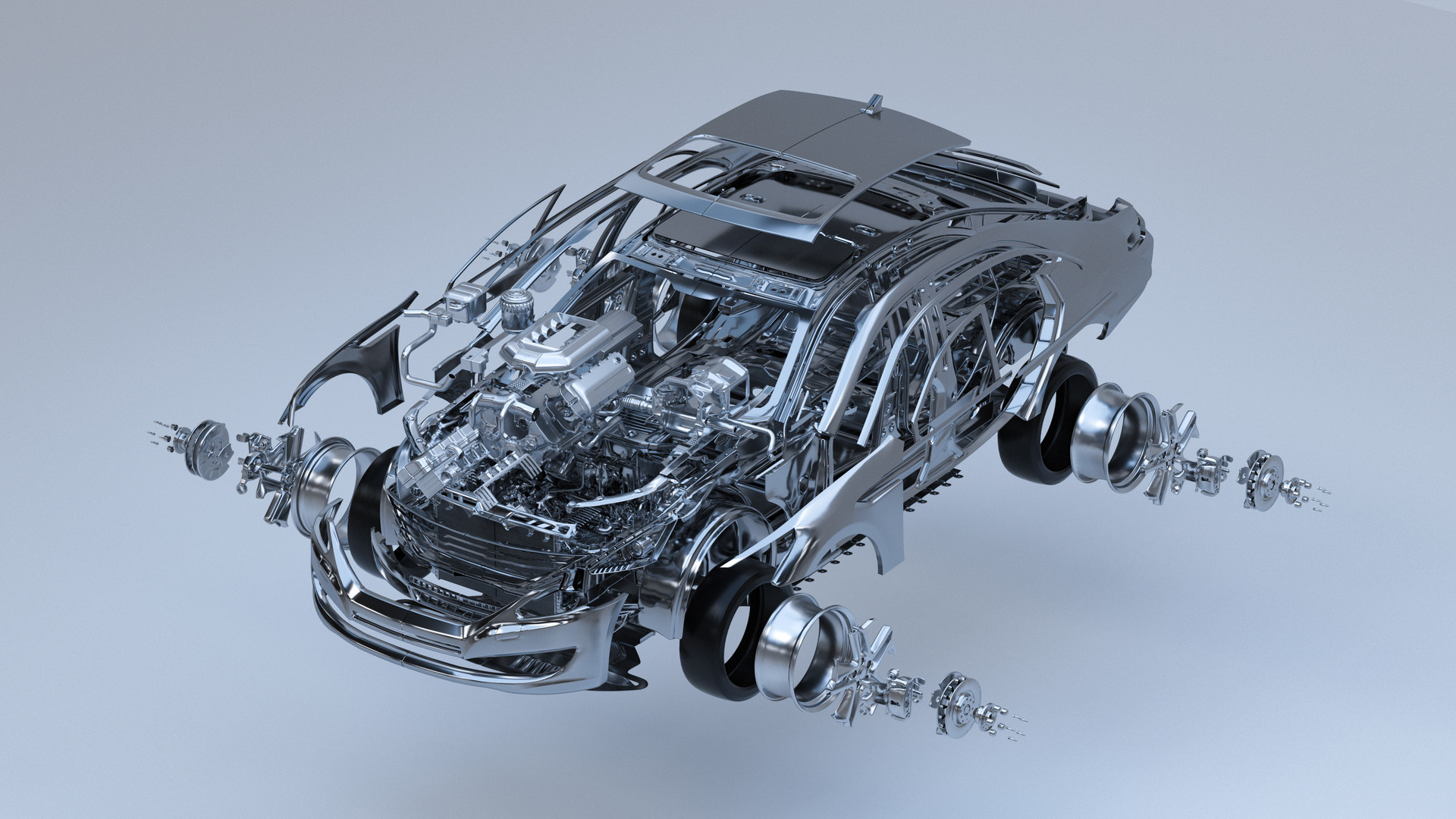

The Power of Forged Automotive Parts

In the fast-paced world of automotive manufacturing, every component counts. Among the unsung heroes of this industry are forged automotive parts. These components are not just about raw materials; they represent a leap in technology and efficiency that's driving the future of vehicles. Buckle up as we delve into this fascinating subject!

What Are Forged Automotive Parts?

So, what exactly are these forged automotive parts? Well, they're manufactured through a process known as forging, where metal is shaped and formed under high pressure. This method results in parts that are stronger and more durable than those made through traditional casting methods. Think of it like molding clay into a robust statue rather than a flimsy figurine!

The Advantages of Forged Parts

Let's get down to brass tacks. Why should manufacturers consider forged automotive parts? Here are a few compelling reasons:

- Strength and Durability: The forging process aligns the grain structure of the metal, enhancing its strength. This means parts can withstand higher stress and strain, making them ideal for high-performance vehicles.

- Cost-Efficiency: While the initial investment might be higher, the long-term benefits of durability and reduced maintenance costs make them a smart choice.

- Precision Engineering: Forged parts can be made to very precise specifications, ensuring they fit perfectly within the vehicle's assembly.

Real-World Applications

Now, let's take a gander at some real-world applications of forged automotive parts. For instance, many high-end sports cars utilize forged aluminum and titanium components. These materials not only reduce weight but also improve acceleration and handling. For example, take the renowned Porsche 911—its performance is partly attributed to the lightweight forged parts that help it zoom around corners like a dream!

Case Study: The Evolution of Forging in the Industry

One standout case in the automotive world is Ford Motor Company. By integrating forged automotive parts into their production lines, they've seen a significant uptick in vehicle reliability and customer satisfaction. The Ford F-150, for instance, has benefited from these innovations, boasting enhanced towing capabilities and fuel efficiency, all thanks to its robust forged components.

Challenges in the Forging Process

Of course, it's not all sunshine and rainbows. The forging process can be quite complex and requires specialized equipment and skilled labor. Additionally, quality control is paramount. A single flaw in a forged automotive part can lead to catastrophic failures down the line. Manufacturers need to be on their toes, ensuring that every piece meets stringent safety and quality standards.

Looking Ahead: The Future of Forged Parts

As we peer into the crystal ball, the future of forged automotive parts looks bright. With advancements in technology, including automation and AI, the forging process is becoming more efficient, allowing for even greater precision and lower costs. Imagine a world where every car on the road is not just a vehicle but a masterpiece of engineering!

Conclusion

In conclusion, forged automotive parts are revolutionizing the automotive industry, providing unmatched strength, precision, and reliability. As manufacturers continue to embrace these innovations, we can expect to see even more remarkable advancements in vehicle performance and safety. So, the next time you hit the road, remember that the parts beneath your car's hood might just be forged from excellence!

Recommended