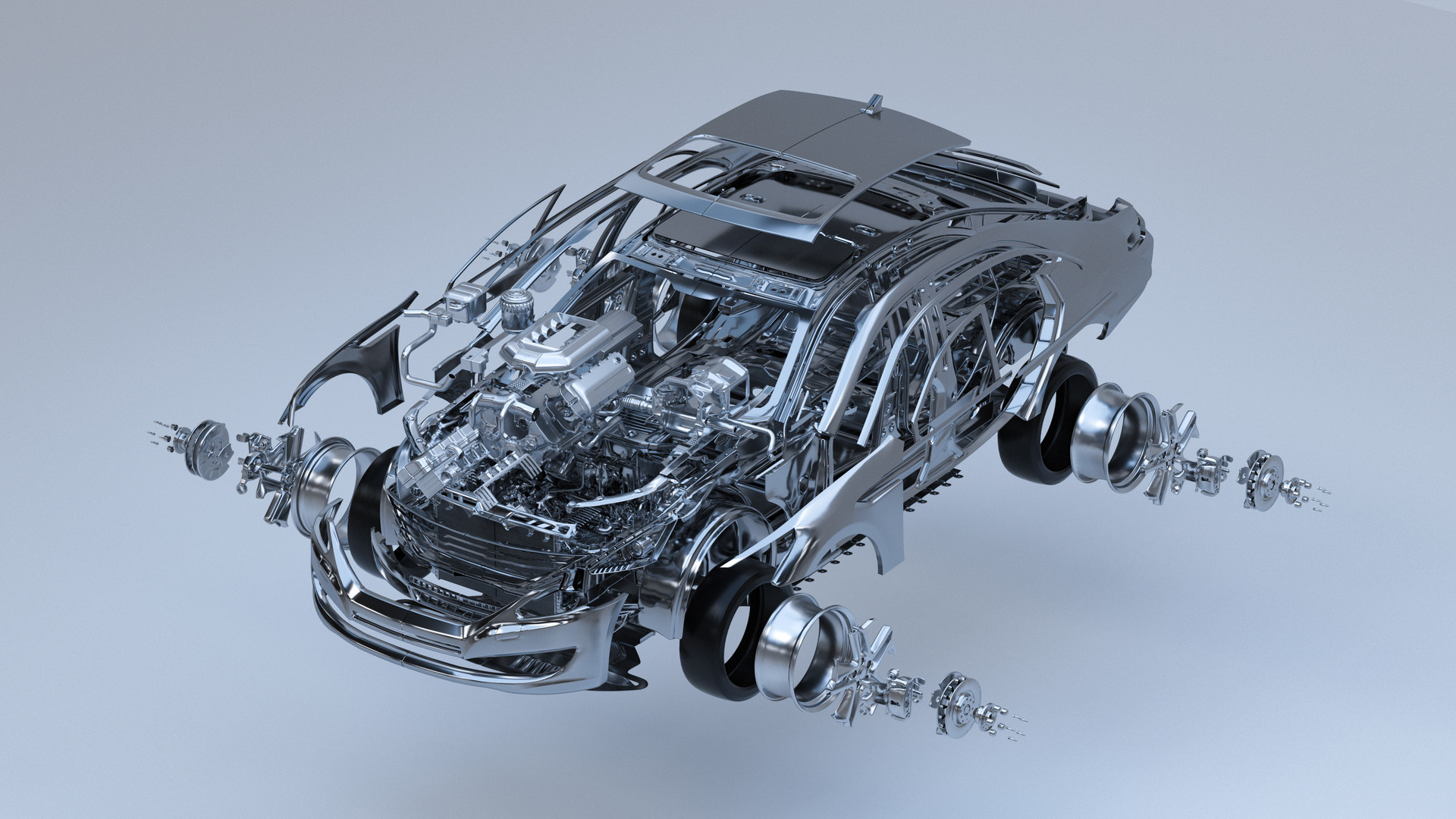

The Rise of Forged Automotive Parts: Shaping the Future of the Industry

Time:

06 Sep,2025

The Rise of Forged Automotive Parts

In the ever-evolving world of automotive manufacturing, the phrase "forged automotive parts" has been making quite the splash lately. But what's the big deal? Well, buckle up, folks! We're about to take a deep dive into how these parts are not just a trend but a revolution in the industry.

What Are Forged Automotive Parts?

Forged automotive parts are components that have been shaped and strengthened through a process of controlled deformation. This can be achieved through various methods like hammering or pressing, which leads to a denser molecular structure. The result? Parts that are stronger, lighter, and more durable than their cast counterparts. It's like comparing a steel wall to a flimsy cardboard box—there's really no contest!

Why the Buzz?

So, why all the fuss about these forged parts? Well, aside from their apparent strength, they also offer enhanced performance and efficiency. Imagine driving a car that uses lightweight forged components, allowing for better fuel consumption and handling. It's a game-changer! And let's face it, who doesn't want to save a bit at the pump while enjoying the thrill of a well-handled ride?

Industry Trends: Forged Parts on the Rise

In recent years, the automotive industry has seen a significant shift towards the use of forged automotive parts. This trend is fueled by the relentless pursuit of innovation and efficiency. Automotive manufacturers are racing against the clock to meet new regulations and consumer demands. With electric vehicles (EVs) gaining traction, the need for lightweight materials has never been more pressing.

Sustainability Matters

Moreover, as the industry strives for sustainability, forged parts fit right into the picture. They tend to produce less waste during manufacturing and can be recycled more efficiently than traditional parts. It's a win-win, folks! Not only do manufacturers benefit from improved performance, but they also contribute to a greener planet. Talk about driving change!

Challenges Ahead

But let's not sugarcoat it; it's not all rainbows and butterflies. The transition to forged automotive parts comes with its own set of challenges. For one, the initial cost of forging can be higher than traditional processes. Plus, there's a learning curve for manufacturers who are used to conventional methods. But hey, nothing worth having comes easy, right?

A Bright Future

Despite the hurdles, the future of forged automotive parts looks bright. As technology advances and manufacturers adapt, we can expect to see even more innovative applications. From performance vehicles to everyday cars, the impact of these parts will resonate throughout the industry.

Conclusion: The Road Ahead

In conclusion, the rise of forged automotive parts is not just a passing phase; it's a transformative movement. As the automotive industry continues to evolve, embracing the strength and efficiency of forged parts will be crucial. So, the next time you're cruising down the highway, take a moment to appreciate the power of these remarkable components. They're not just parts—they're the backbone of the automotive future!

Recommended